As specialists in water pressure management, we are expert hydro pneumatic tank manufacturers and suppliers offering solutions designed for optimal performance and longevity. Our hydro pneumatic pressure tank systems feature advanced technology that ensures consistent water pressure while minimizing pump cycling.

Every hydro pneumatic tank system is engineered for:

The Challenger™ pressure tank series delivers versatile performance across multiple applications, including booster systems, thermal expansion, irrigation networks, and hydraulic hammer protection.

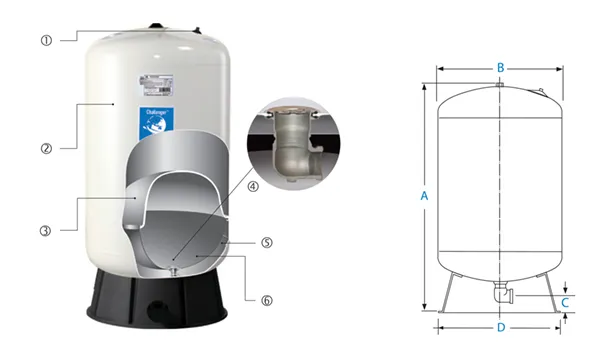

At the heart of each tank lies our revolutionary patented CAD-2 diaphragm technology—a precision-engineered solution that combines efficiency with cost-effectiveness. This advanced system features a 100% butyl diaphragm with exceptional chlorine resistance, coupled with a precision-molded copolymer polypropylene liner that creates superior separation between air and water.

The innovative design incorporates a positive-lock internal clench ring that securely holds drawdown water within a pre-charged air environment, maintaining optimal separation between the diaphragm and tank wall. This creates an "air buffer" that significantly reduces condensation issues. Manufactured with FDA-approved high-grade butyl material, the diaphragm assembly creates a completely non-corrosive water chamber for superior purity and durability.

The exterior showcases an almond-colored two-part polyurethane finish applied over an epoxy undercoating, providing exceptional protection against UV radiation and salt spray exposure. The air chamber's fixed O-ring and closed-cell foam sealing ensure years of leak-free, maintenance-free operation.

Every Challenger™ tank undergoes comprehensive quality testing at multiple production stages to guarantee structural integrity and performance excellence. These premium steel pressure vessels represent the industry's highest standard and deliver unmatched value for your investment.

Each system comes with complete installation support and maintenance guidance, ensuring optimal performance and extended service life.

Healthcare facilities

Educational institutions

Irrigation systems

Residential complexes

Industrial buildings