- Home

- / Product

Pressure Wave

Design Features

Diaphragm design

Diaphragm design Patented stainless steel water connection

Patented stainless steel water connection Virgin polypropylene liner

Virgin polypropylene liner Reinforced connection plate on inline models 8L and up

Reinforced connection plate on inline models 8L and up Two-part polyurethane primed paint finish

Two-part polyurethane primed paint finish Leak-free O-ring sealed air valve

Leak-free O-ring sealed air valve Replaceable tank base / tank feet / pump stand

Replaceable tank base / tank feet / pump stand Comprehensive testing

Comprehensive testing Maintenance-free

Maintenance-free

PressureWave™ tanks are ideally suited for a wide range of applications, including booster systems, thermal expansion, irrigation systems, and hydraulic hammer arresting. The PressureWave Series is constructed of a virgin polypropylene liner combined with an FDA approved high-grade butyl diaphragm. This is held against the wall of the tank with a steel clench ring. The brass air valve, sealed by a threaded o-ring valve cap, prevents air leaks. Water enters the tank through a patented stainless-steel water connection. The diaphragm and liner are both reinforced in specific wear areas for longer life. All internal parts including the air valve are rounded to prevent piercing of the diaphragm in extreme conditions. The water connection uniquely provides a dual water/air seal ensuring a complete leak-free and maintenance-free pressure tank.

On the exterior the almond-colored dual layer polyurethane paint finish provides hundreds of hours of UV and salt spray protection. PressureWave tanks are quality tested at several stages on the production line to ensure the structural integrity of every tank. PressureWave tanks represent the best value for the investment and are the best quality pressure vessels available today.

Construction of PressureWave™ tank

- Leak-free, O-ring sealed air valve cap

- Carbon steel tank shell with two-part polyurethane / epoxy primed paint finish

- Patented CAD-2 diaphragm design

- Stainless steel water connection

- Condensation reducing design

- Virgin Polypropylene Liner

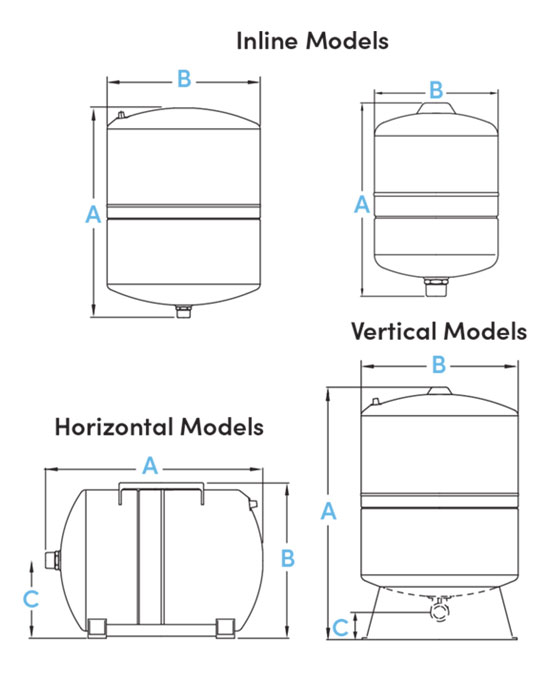

Specifications

- Product Series Name :- PressureWave

- Nominal Volumes :- 2 - 150 L / 0.5 - 39.6 gal

- Min. Operating Temperature :- -10°C / 14°F (Avoid Freezing)

- Max. Operating Temperature :- 90°C / 194°F

- Max. Operating Pressure :- 10 bar | 150 psi (Available in 16 and 25 bar as Max and UltraMax series)

- Factory Pre-charge :- 1.9 bar | 28 psi

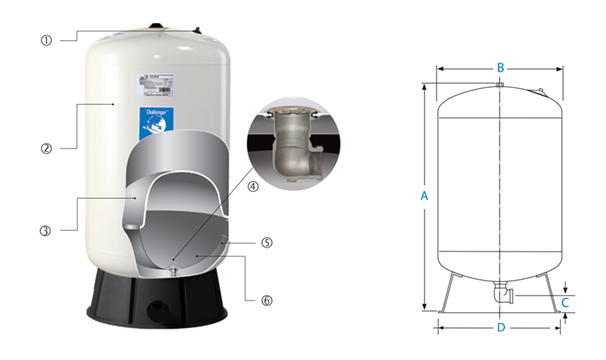

Challenger Series

Features

Patented CAD-2 diaphragm technology

Patented CAD-2 diaphragm technology CE/PED, WRAS, ACS, ISO-9001, Gost, Evrazes approved

CE/PED, WRAS, ACS, ISO-9001, Gost, Evrazes approved Stainless steel water connection

Stainless steel water connection Condensation reducing design

Condensation reducing design

Two part polyurethane, epoxy primed paint finish

Two part polyurethane, epoxy primed paint finish Leak free air valve cap sealed with closed cell foam

Leak free air valve cap sealed with closed cell foam  Comprehensive testing

Comprehensive testing No maintenance

No maintenance

Challenger™ tanks are ideally suited for a wide range of applications, including booster systems, thermal expansion, heating expansion, irrigation systems, and hydraulic hammer arresting

Water Chamber, Patented Controlled Action Design:

Efficient and cost effective, Challenger™ tanks are designed with a patented controlled action CAD-2 diaphragm assembly. It features a chlorine resistant 100% butyl diaphragm with a precision molded copolymer polypropylene liner for superior air and water separation. The CAD-2 diaphragm assembly is clenched together with a positive lock internal clench ring which contains drawdown water in a pre-charged air atmosphere, thus providing separation between the diaphragm and tank wall. This “air buffer” design means few problems with condensation. Constructed with an FDA approved high grade butyl, the diaphragm assembly seals water in a true non-corrosive chamber.

On the exterior, the almond colored two part polyurethane paint finish over an epoxy undercoating provides hundreds of hours of UV and salt spray protection.

The air chamber is sealed with a fixed o-ring and closed cell foam and will provide many years of leak free and service free life. Challenger™ tanks are quality tested at several stages on the production line to insure the structural integrity of every tank. Challenger™ tanks are the best steel pressure vessels in the market today and represent the best value for the investment.

- Leak-free, O-ring sealed air valve cap

- Carbon steel tank shell with two-part polyurethane / epoxy primed paint finish

- Patented CAD-2 diaphragm design

- Stainless steel water connection

- Condensation reducing design

- Virgin Polypropylene Liner

Applications

Hospitals, Hotels

Hostels, Complexes

Schools & Colleges

Drip Irrigation

Sprinkler

Residential

Bungalow

Building Curing

Group Houses

Appartments